In the age of global warming, climate change and plastic pollution, now is the time to be evaluating the industry’s efforts in being efficient and sustainable. The ways to earn the accolade of being ‘green’ are many and varied - but one easy solution is to clean exhausts and emissions. As the International Maritime Organization (IMO) is actively working to reduce vessel waste, new legislations are changing the way superyachts are being built.  Photo: Charl van Rooy / SuperYacht TimesMore often than not, new-builds will now include a Diesel Particulate Filter (DPF) and/or a Selective Catalytic Reduction (SCR) system. These future-proof systems eliminate 98% of expelled soot, reduce NOx to below IMO Tier III levels and attenuate noise by up to 45dB(A). As this state-of-the-art technology becomes an essential asset in the engine room, SuperYacht Times asks the system manufacturer Emigreen how these exhaust gas after-treatment systems work.

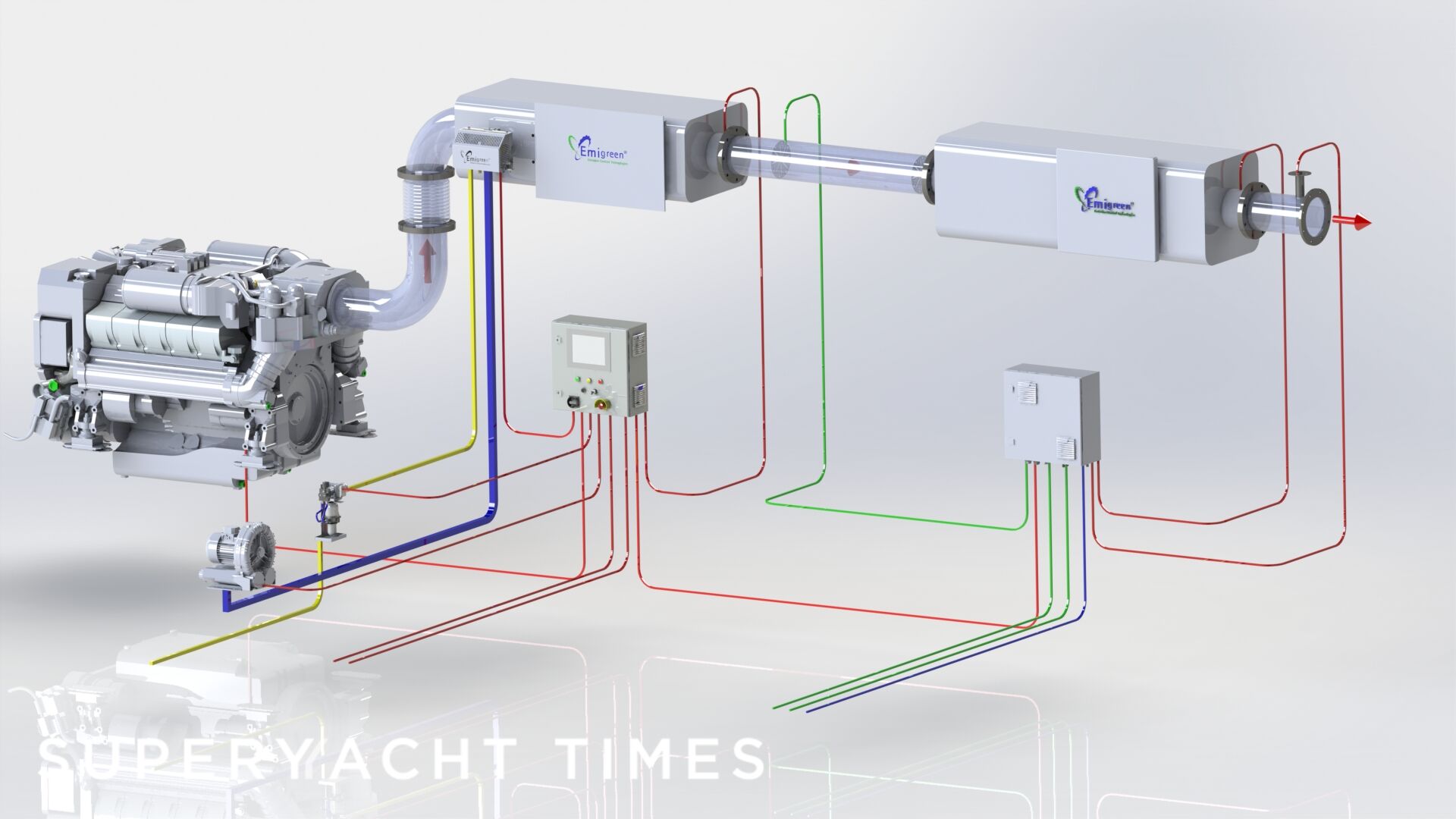

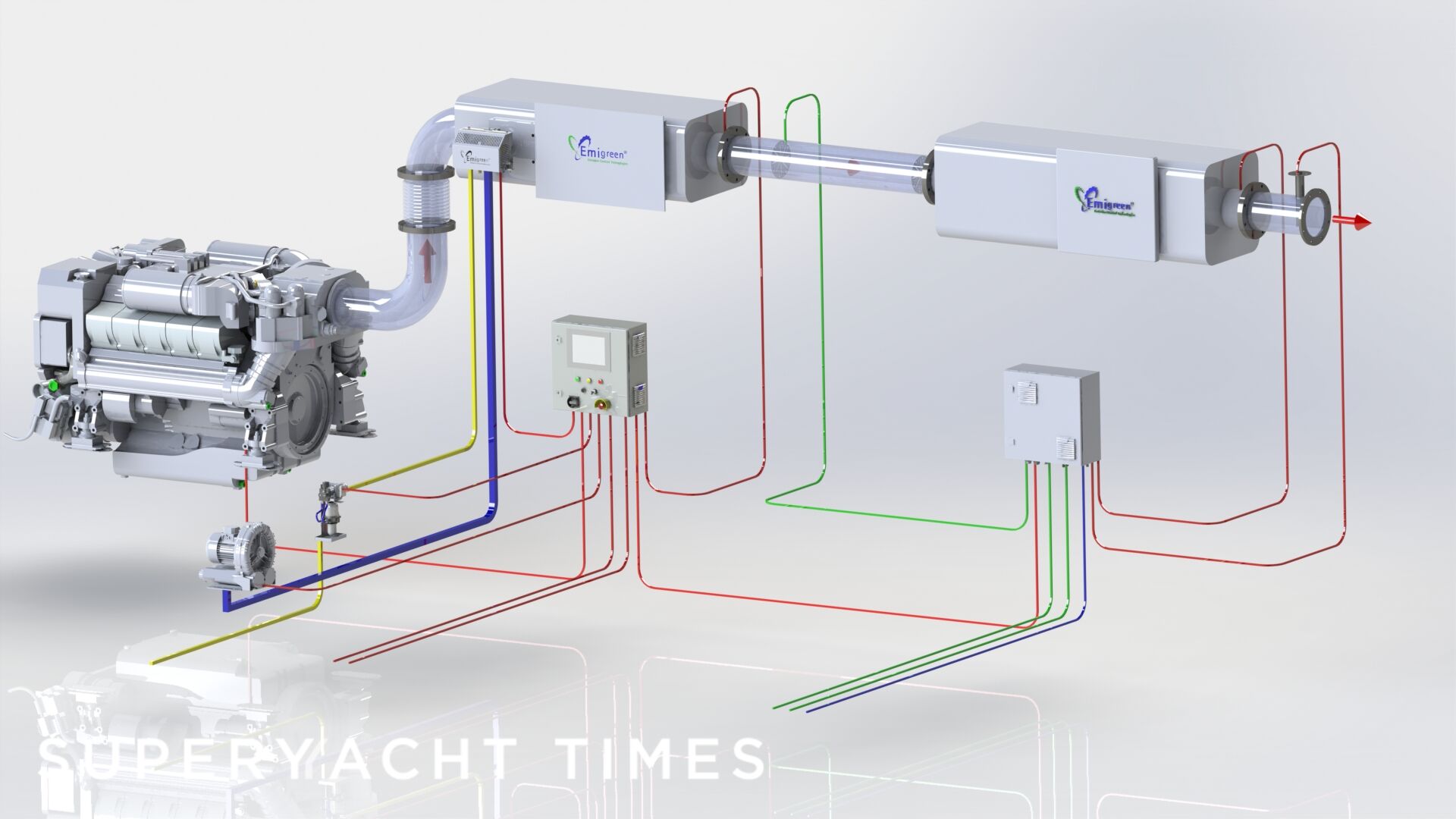

Photo: Charl van Rooy / SuperYacht TimesMore often than not, new-builds will now include a Diesel Particulate Filter (DPF) and/or a Selective Catalytic Reduction (SCR) system. These future-proof systems eliminate 98% of expelled soot, reduce NOx to below IMO Tier III levels and attenuate noise by up to 45dB(A). As this state-of-the-art technology becomes an essential asset in the engine room, SuperYacht Times asks the system manufacturer Emigreen how these exhaust gas after-treatment systems work. By catching 98% of the visible particles from exhaust pipes, a DPF exhaust gas cleaning system ensures that no carbon particles are left on the deck or in the surrounding waters. With their next-generation systems, Emigreen has made a compact and reliable solution with various options to incorporate SCR and DPF systems either together or independently into one silencer housing - meaning that harmful NOx and noise emissions are a thing of the past, as is the smell of engine exhaust and soot.

By catching 98% of the visible particles from exhaust pipes, a DPF exhaust gas cleaning system ensures that no carbon particles are left on the deck or in the surrounding waters. With their next-generation systems, Emigreen has made a compact and reliable solution with various options to incorporate SCR and DPF systems either together or independently into one silencer housing - meaning that harmful NOx and noise emissions are a thing of the past, as is the smell of engine exhaust and soot.  Photo: Charl van Rooy / SuperYacht TimesA high-performance exhaust silencer is integrated inside the system and can be controlled on a user-level base by a touch screen in the engine room and monitored remotely on the bridge. This is where simple settings such as a forced regeneration can be used to pre-schedule ash removals. Whatever the preferred method of maintenance is, Emigreen can tailor the system to suit the project at hand.

Photo: Charl van Rooy / SuperYacht TimesA high-performance exhaust silencer is integrated inside the system and can be controlled on a user-level base by a touch screen in the engine room and monitored remotely on the bridge. This is where simple settings such as a forced regeneration can be used to pre-schedule ash removals. Whatever the preferred method of maintenance is, Emigreen can tailor the system to suit the project at hand.  A vacuum cleaner and compressed air work together to remove ash easily from the system. On the rare occasion the elements need to be outed from the structure, the mounting frame is simply lifted out of the housing. To ensure that the superyacht can keep cruising with noise attenuation in place, the solution can be supplied with optional additional acoustic elements.

A vacuum cleaner and compressed air work together to remove ash easily from the system. On the rare occasion the elements need to be outed from the structure, the mounting frame is simply lifted out of the housing. To ensure that the superyacht can keep cruising with noise attenuation in place, the solution can be supplied with optional additional acoustic elements.  Photo: Charl van Rooy / SuperYacht TimesThe solution can fit any superyacht project - whether it be for a refit or a new-build - a system can be incorporated into the design at any stage. Emigreen’s after-treatment systems are custom designed to merge seamlessly into any engine room; as proven on board one of the world’s largest sailing superyachts, which features four of the systems. Here, the yacht’s general arrangement instantly benefited as the compact system requires only a fraction more of space than the silencer in the engine room. Plus, the system works in replacement of the yacht’s silencer which also frees up space and lessens the load.

Photo: Charl van Rooy / SuperYacht TimesThe solution can fit any superyacht project - whether it be for a refit or a new-build - a system can be incorporated into the design at any stage. Emigreen’s after-treatment systems are custom designed to merge seamlessly into any engine room; as proven on board one of the world’s largest sailing superyachts, which features four of the systems. Here, the yacht’s general arrangement instantly benefited as the compact system requires only a fraction more of space than the silencer in the engine room. Plus, the system works in replacement of the yacht’s silencer which also frees up space and lessens the load.  To grow the positive reputation for the industry, owners and their teams can play their part and install more and more eco-friendly innovations onboard. With Emigreen’s DPF and SCR system combination packages, the aim is to eliminate damaging practices which have negative connotations on the industry; such as fouling in ports or the image of black smoke trailing behind superyachts.

To grow the positive reputation for the industry, owners and their teams can play their part and install more and more eco-friendly innovations onboard. With Emigreen’s DPF and SCR system combination packages, the aim is to eliminate damaging practices which have negative connotations on the industry; such as fouling in ports or the image of black smoke trailing behind superyachts.  Photo: Charl van Rooy / SuperYacht TimesAs more and more ports opt to keep yachts without exhaust gas cleaning systems anchored outside, get ahead of the game and find out exactly how one can be installed on your superyacht via the contact details found below.

Photo: Charl van Rooy / SuperYacht TimesAs more and more ports opt to keep yachts without exhaust gas cleaning systems anchored outside, get ahead of the game and find out exactly how one can be installed on your superyacht via the contact details found below.